Our main goal is "LOW cost & High quality". For this goal, We established Our Own Original production line,

which was developed with our high technologies.

And Our excellent management System controls every single scene of product's manufacturing process,

from receiving Orders to shipping products.

Square 125mm×125mm. Length 3〜4m.

Product standard

We, Jonan Steel Corporation, manufacture high quality steel rods for reinforced concrete based on advanced technology and cutting-edge facilities.

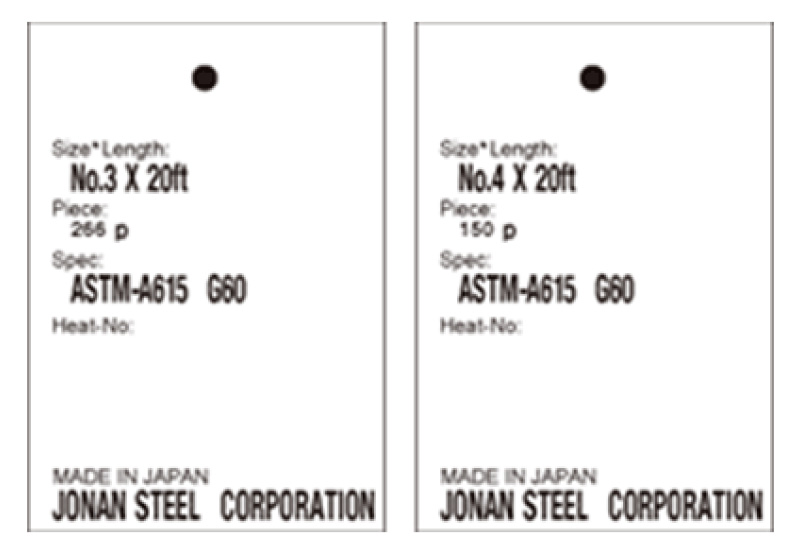

ASTM STANDARDS

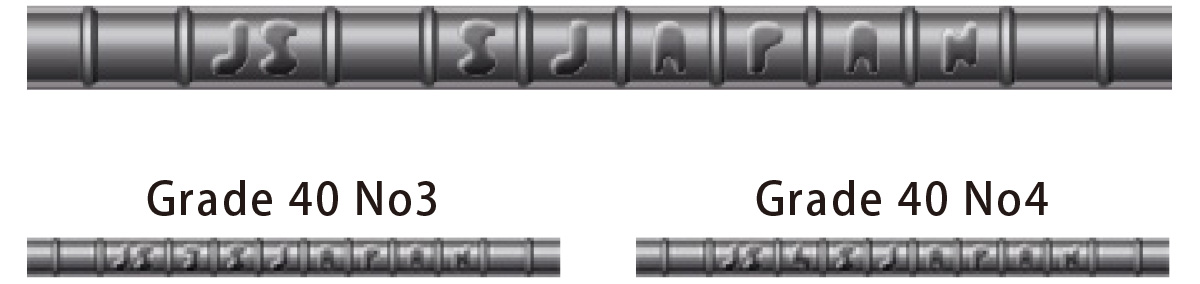

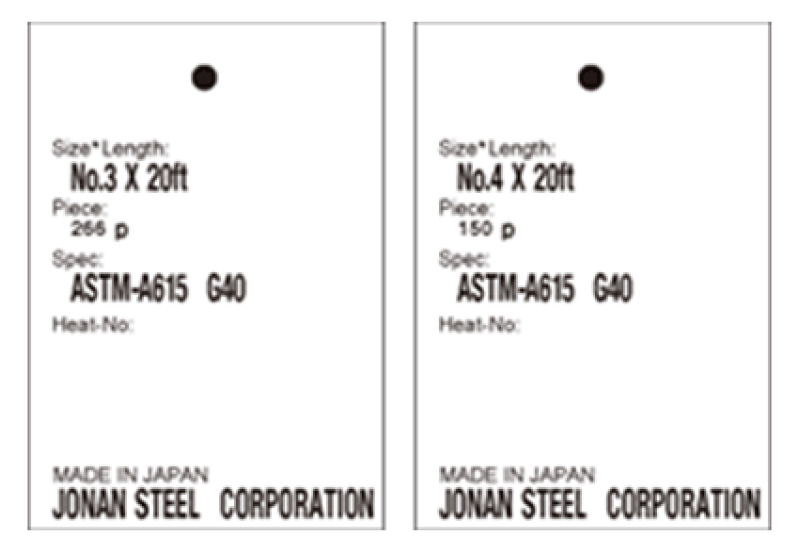

Product display

Our products, manufactured with solid technique, have received worldwide acclaim, and have established its position as a trusted brand.

Deformed bar/Roll mark/Polyester tag

ASTM-A615 Grade 40

ASTM-A615 Grade 60

Product standard list

We conduct inspections on our products to check many factors such as chemical composition, shape, dimension, mechanical property, etc. These are done under our strict quality control system, and enables us to manufacture high quality products.

Symbol of grade

| Division | Standards | Symbol of grade |

|---|---|---|

| Deformed steel bars | A615/A615M | G-40 |

| G-60 | ||

| A706/A706M | G-60 | |

| G-80 |

Chemical composition(%)

| Standards | Symbol ofgrade | C | Si | Mn | P | S | C.E(*) |

|---|---|---|---|---|---|---|---|

| A615/A615M | G-40 | ー | ー | ー | ー | 0.045 max. | ー |

| G-60 | |||||||

| A706/A706M | G-60 | 0.30 max. | 0.50 max. | 1.50 max. | 0.035 max. | 0.045 max. | 0.055 max. |

| G-80 |

*C.E.(%)=C+(Mn/6)+(Cu/40)+(Ni/20)+(Cr/10)-(Mo/50)-(V/10)

Mechanical properties

| Standards | Symbol of grade | Yield point or proof stress psi(Mpa) | Tensile strength psi(Mpa) | Tensile test piece | Elongation % | Bendability | |

|---|---|---|---|---|---|---|---|

| Bend angle | Inside radius 3(10)・4(13)・5(16) | ||||||

| A615/A615M | G-40 | 40000 min. (280) | 60000 min. (420) | Like rolling | 12min.(*) | 180° | 3.5 × Nominal diameter |

| A615/A615M | G-60 | 60000 min. (420) | 90000 min. (620) | Like rolling | 9min. | 180° | 3.5 × Nominal diameter |

| A706/A706M | G-60 | 60000 to 78000(420 to 540) | 80000 min. (550)(*) | Like rolling | 9min. | 180° | 3.5 × Nominal diameter |

| A706/A706M | G-80 | 80000 to 98000(550 to 675) | 100000 min. (690)(※2) | Like rolling | 9min. | 180° | 3.5 × Nominal diameter |

*1:No3.(10) is 11% min.

*2:Tensile strength shall not be less than 1.25 times the actual yield strength.

Dimension,mass and allowable limits of knots

| Bar Designation No. | Nominal Weight, lb/ft (Nominal Mass,kg/m) | Nominal Dimensions | Deformation Requirements, in.(mm) | ||||

|---|---|---|---|---|---|---|---|

| Diameter,in. (mm) | Cross-Sectional Area in, (mm2) | Perimeter,in. (mm) | Maximum Average Spacing | Minimum Average Height | Maximum Gap (Chord of 12.5 % of Nominal Perimeter) | ||

| 3(10) | 0.376(0.560) | 0.375(9.5) | 0.11(71) | 1.178(29.9) | 0.262(6.7) | 0.015(0.38) | 0.143(3.6) |

| 4(13) | 0.668(0.994) | 0.500(12.7) | 0.20(129) | 1.571(39.9) | 0.350(8.9) | 0.020(0.51) | 0.191(4.9) |

| 5(16) | 1.043(1.552) | 0.625(15.9) | 0.31(199) | 1.963(49.9) | 0.437(11.1) | 0.028(0.71) | 0.239(6.1) |

Tolerances on mass of one piece

| No. | Tolerance |

|---|---|

| 3(10)・4(13)・5(16) | -6% min. |

Mass table

Exampies pf the packing of our products can be seen her.

Packing(ASTM A615 Rebar to the USA)

| Size # | Dia.(") | Dia.(mm) | Length(ft) | (m) | weight(lbs/ft) | (kg/m) | Bundle(Sub) | (pcs/bdl.) | (kg/bdl.) |

|---|---|---|---|---|---|---|---|---|---|

| 3 | .3/8 | 9.5 | 20 | 6.096 | 0.3763 | 0.56 | 38 | 266 | 907 |

| 30 | 9.144 | 0.3763 | 1,362 | ||||||

| 40 | 12.192 | 0.3763 | 1,814 | ||||||

| 4 | .1/2 | 12.7 | 20 | 6.096 | 0.6679 | 0.994 | 30 | 150 | 909 |

| 30 | 9.144 | 0.6679 | 1,363 | ||||||

| 40 | 12.192 | 0.6679 | 1,818 | ||||||

| 5 | .5/8 | 15.9 | 20 | 6.096 | 1.0429 | 1.552 | 24 | 96 | 908 |

| 30 | 9.144 | 1.0429 | 1,362 | ||||||

| 40 | 12.192 | 1.0429 | 1,816 |

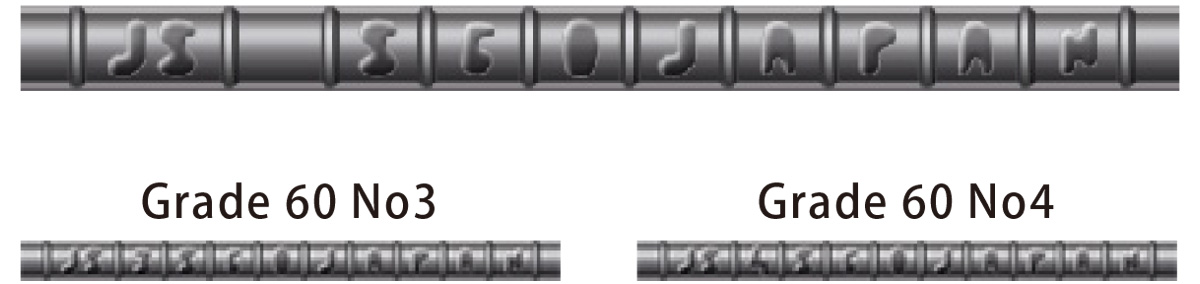

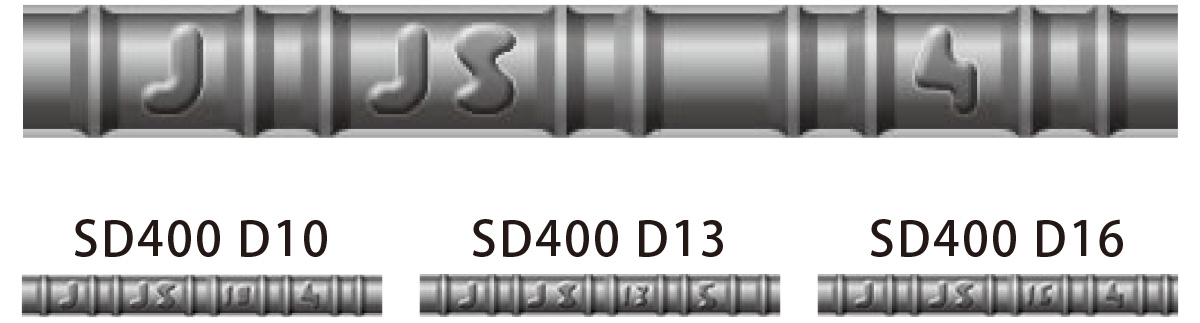

KS STANDARDS

Product display

Our products, manufactured with solid technique, have received worldwide acclaim,and have established its position as a trusted brand.

Deformed bar/Roll mark/Polyester tag

SD400

SD500

Product standard list

We conduct inspections on our products to check many factors such as chemical composition, shape, dimension, mechanical property, etc. These are done under our strict quality control system, and enables us to manufacture high quality products.

Symbol of grade

| Division | Standards | Symbol of grade |

|---|---|---|

| Deformed steel bars | KS D 3504 | SD400 |

| SD500 |

Chemical composition(%)

| Standards | C | Si | Mn | P | S | N | Ceq |

|---|---|---|---|---|---|---|---|

| SD400 | - | - | - | 0.045 max. | 0.045 max. | - | - |

| SD500 | - | - | - | 0.040 max. | 0.040 max. | - | - |

Mechanical properties

| Standards | Symbol of grade | Yield point or proof stress psi(Mpa) | Tensile strength psi(Mpa) | Elongation % | Bendability | |

|---|---|---|---|---|---|---|

| Bend angle | Inside radius | |||||

| SD400 | 400~520 | ≧YP×1.15 | Equivalent to No.2 | Equivalent to No.3 | 180° | 2 × Nominal diameter |

| Equivalent to No.3 | Equivalent to No.3 | |||||

| A615/A615M | 500~650 | ≧YP×1.08 | Equivalent to No.2 | Equivalent to No.3 | 135° | 2.5 × Nominal diameter for diameter D16 or more and less than D22 |

| Equivalent to No.3 | 14min. | |||||

Dimension,mass and allowable limits of knots

| Designation | Unit mass kg/m | Nominal diameter(d)mm | Nominal section area(s)cm2 | Nominal peripheral length(I)cm | Maximum value mm of average interval between knots mm | Height of knot | Maximum value of sum of clearance between knots mm | Angle between knot and axial line | |

|---|---|---|---|---|---|---|---|---|---|

| Minimum value mm | Maximum value mm | ||||||||

| D10 | 0.560 | 9.53 | 0.7133 | 3.0 | 6.7 | 0.4 | 0.8 | 7.5 | 45°min. |

| D13 | 0.995 | 12.7 | 1.267 | 4.0 | 8.9 | 0.5 | 1.0 | 10.0 | |

| D16 | 1.56 | 15.9 | 1.986 | 5.0 | 11.1 | 0.7 | 1.4 | 12.5 | |

Tolerances on length

| Length | Tolerance |

|---|---|

| 7m or under | +40mm 0 |

| over 7m | For each increase of 1m in length or its fraction,further 5mm shall be added to the tolerances on the plus side given above.The maximum value , however , shall be limited to 120mm. |

Tolerances on mass of one piece

| Dimensions | Tolerance |

|---|---|

| Designation over D10 up to and incl. D16 | ±6% |

| Designation over D16 up to and incl. D29 | ±5% |

Tolerances on mass of one set

| Dimensions | Tolerance |

|---|---|

| Designation over D10 up to and incl. D16 | ±5% |

| Designation over D16 up to and incl. D29 | ±4% |

Mass table

Exampies pf the packing of our products can be seen her.

Packing(KS Rebar to the Korea)

| Size # | Dia.(mm) | (m) | (kg/m) | Bundle(Sub) | (pcs/bdl.) | (kg/bdl.) |

|---|---|---|---|---|---|---|

| D10 | 9.53 | 8 | 0.56 | 42 | 420 | 1,882 |

| D13 | 12.7 | 0.995 | 30 | 240 | 1,910 | |

| D16 | 15.9 | 1.56 | 15 | 150 | 1,872 |

OTHER STANDARDS

Product display

Our products, manufactured with solid technique, have received worldwide acclaim, and have established its position as a trusted brand.

Deformed bar/Roll mark

BSD16

* BS-SPEC is available. (water-cooled control)

* I examine it and it produces it if available and sells it to other standards.

Product standard list

We conduct inspections on our products to check many factors such as chemical composition, shape, dimension, mechanical property, etc. These are done under our strict quality control system, and enables us to manufacture high quality products.

Symbol of grade

| Standards | C | Si | Mn | P | S | Cu | N | Ceq(*) |

|---|---|---|---|---|---|---|---|---|

|

BS:B500B (2005) |

0.22 (0.24) |

ー | ー |

0.050 (0.055) |

0.050 (0.055) |

0.80 (0.85) |

0.012 (0.014) |

0.50 (0.52) |

|

BS:460B (1997) |

0.25 (0.27) |

ー | ー |

0.050 (0.055) |

0.050 (0.055) |

ー |

0.012 (0.013) |

0.51 (0.54) |

(*)Ceq = C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

Mechanical properties

| Standards | Yield point | Tensile/Yield point ratio | Elongation | Elongation (at the time of the maximum stress) |

|---|---|---|---|---|

| BS:B500B (2005) |

500Mpa(650 max.) | 1.08 | - | 5.0% |

| BS:460B (1997) |

460N/mm2 | 1.08 | 14% | 5.0% |

Bending test

| Standards | Nominal diameter (mm) | Mandrel diameter |

|---|---|---|

| BS:B500B(2005) | 16min. | 4d |

| BS:460B(1997) | 16min. | 3d |

Nominal section area/Unit mass/Tolerance

| Standards | Nominal diameter (mm) |

Nominal section area | Unit mass (Kg/m) |

Tolerance |

|---|---|---|---|---|

| BS:B500B(2005) | 10 | 78.5mm | 0.617 | ±4.5% |

| 12 | 113mm | 0.888 | ||

| 16 | 201mm | 1.58 | ||

| BS:460B(1997) | 10 | 78.5mm | 0.616 | ±6.5% |

| 12 | 113.1mm | 0.888 | ±4.5% | |

| 16 | 201.1mm | 1.579 | ±4.5% |

Tolerances on length

| Standards | Allowance |

|---|---|

| BS:B500B(2005) | -0~+100mm |

| BS:460B(1997) | ±25mm |