Company Profile

| Company name | Jonan Steel Corporation |

|---|---|

| President & CEO | Representative President Takashi Sawa |

| Capital | ¥100,000,000 |

| Date established | March 1955 |

| Main client |

HANWA CO.,LTD. Marubeni-Itochu Steel Inc. NIPPON STEEL TRADING CORPORATION JFE Shoji Trade Corporation Metal One Corporation SHIBAMOTO & CO.,LTD. |

History

-

1955

March

Kenji Kakihara, the founder of this company, established Jonan Steel Shokai in Omori-kita, Ota-ku, Tokyo, to sell steel materials as a private management company.

-

1967

December

Jonan Steel Mill Corporation purchased land at 5-13-35 Ryoke, Kawaguchi city, and started to construct a new rolling plant as a first phase of new mill constraction.

-

1969

November

The company built a steel making plant as the second phase of the construction. This plant started production with a 20-ton electric furnace. The continuous production system from the steel-making process to the rolling process started. Capital was increased to ¥48 million with investment by Tokyo Small and Medium Business Investment & Consultation Co.,Ltd.

-

1971

November

Authorized to use Japan Industrial Standard (JIS) Mark indication for reinforcing bar steel.

-

1972

June

Continuous casting machine was installed.

-

1973

August

The 20-ton electric furnace in the steel-making plant was replaced by a 40-ton electric furnace. Rationalization of the rolling line was done, which capabled 15,000 tons of production per month.

-

1982

December

The steel making mill and the rolling mill achieved 25,000 tons production per month.

-

1988

November

Rolling line and accuracy adjustment line were replaced by new lines. Both the steel-making mill and the rolling mill established 40,000-ton production systems.

-

1989

September

The continuous casting machine in the steel-making plant was replaced by a new machine.

-

1994

January

The finishing rolling machine in the rolling plant was replaced by a block mill.

-

1997

January

The oxygen generator was replaced by a new one. The intermediate mill in the rolling plant was replaced by a block mill.

-

1999

December

ISO 9002:1994 certified and registered.

-

2001

March

The Purchasing Department purchased a iron scrap radioactive ray detection monitor.

-

2004

December

The motors of the building dust collectors were changed to inverter-controlled motors to achieve energy saving.

-

2005

May

The motors of the direct-suction dust collectors were changed to inverter-controlled motors to achieve energy saving.

-

2009

April

Authorized to use Korean Industrial Standards (KS) for reinforcing bar steel. (KS D 3504)

-

2010

January

Cooling bed and maintenance facility was renewed.

-

2011

June

ISO 14001:2004 certified and registered.

-

2012

January

Tempcore facility was installed.

-

2012

June

Separately excited type flicker compensating device was replaced, and self-exciting type flicker compensating device was additionally installed.

-

2014

January

Transformer for electric furnance was replaced by a new machine. Continous casting machine was replaced by a new one.

-

2014

February

OHSAS 18001:2007 certified and registered.

-

2015

January

Ladle preheating/drying equipment was replaced by a new one. Product cutting machine was replaced by a new machine.

-

2016

January

Inverter equipment for rolling mill motors were renewed.

-

2017

January

Rolling plant, slit roll reduction ratio updated.

-

2018

July

ISO 14001:2015 certified and registered.

-

2018

October

Electrode regulating control system was replaced.

-

2018

November

ISO 9001:2015 certified and registered.

-

2019

January

Cojet gas injection system was installed.

-

2019

March

New company office completed.

-

2020

January

Liquid oxygen equipment was installed.

-

2020

March

ISO45001 certified and registered.

-

2020

May

The oxygen generator was replaced by a new one.

-

2020

October

Billet straightening device was installed.

-

2024

February

Defects detector was installed.

Work environment

Head Office

Head office completed in March 2019

Factory

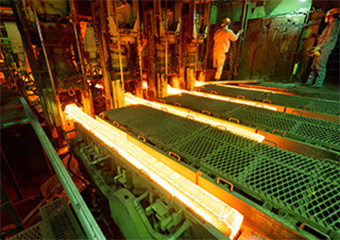

We have a solid foundation as a manufacturer specializing in steel bars, with our headquarters and multiple warehouses in the Kanto region, a major consumer area, as well as factories equipped with cutting-edge equipment.

Company Profile

TM332-0004 11-13, 5-chome, Ryoke, Kawaguchicity, Saitama Prefecture

TEL.048(223)3116

FAX.048(224)7607

■ By public transportation

【By taxi】

Take a taxi from the east exit of Kawaguchi Station

on the JR Keihin-Tohoku line (about 15 minutes).

【By bus】

Take Kokusai Kogyo Bus, Kawa 21. which departs from the east exit of JR Kawaguchi Station. On the

Shikahama-Ryoke route, which goes around Ryoke factory town first, get of at 'Enokibashi' bus stop. from

which it's 5 minutes no foot. If the bus goes around Ryoke 2-chome first, get off at "Sanno-bashi-giwa. from

which it's 7 minutes on foot

Take Kokusai Kogyo Bus. Aka 23 route, departing from the east exit of JR Akabane Station for Nishi-Arai

Station via Arakawa Ohashi, get off at "Enokibashi" bus stop, from which it's 5 minutes on foot.