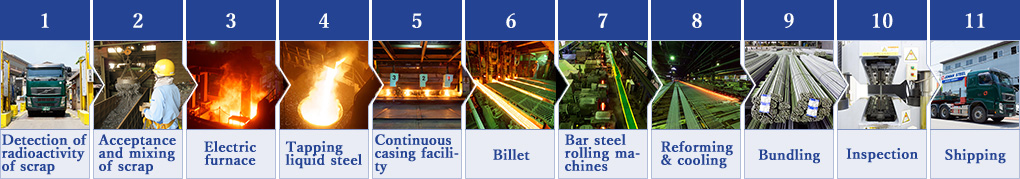

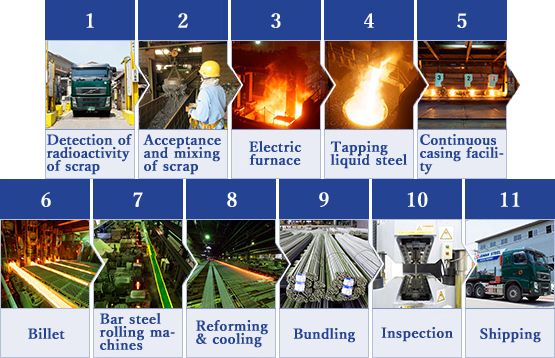

FLOW

Our main goal is “Low & High quality”. For this goal, we established our own original production line, whitch was developed with our high technologies. And our excellent management system controls every single scene of product’s flow, from receiving orders to shipping products.

Detection of radioactivity of scrap

We check if there is radioactive waste in steel scrap by "Radioactive ray detection monitor" as a first step. The inspection is done by trailer track basis. If it contains the waste, the scrap will be returned.

There are so many staffs surround us, which radiant rays is used for, such as medical equipment, various analyzing equipment, etc. We strictly prevent radioactive waste to be in our plant.

Acceptance and mixing of scrap

The scrap iron collected is unloaded using a huge magnet, then the scrap is selected in order by each class and stored in the yard. Later, we mix the scrap iron in order to ensure that the chemical composition will be even when the scrap is melted, then feed the mixed scrap into the electric furnace.

Electric furnace

We melt the scrap iron in an electric furnace using arc discharge. In addition, we adjust chemical compositions by removing impurities from the melted steel and adding auxiliary materials.

Chemical compositions have great influence on the mechanical property of products. We use an analyzing system to inspect the product, and after we have refined the products to meet to our company standards, we top liquid steel in to a ladle.

Tapping liquid steel

One charge is about 70 tons, and we can produce about 25 charges per day.

Continuous casing facility

Next, the liquid steel from the electric furnace is carried to the continuous casting machine, and the billets which is the base materials for steel reinforcement bars are produced here.

Billet

A billet is a block of steel in a square bar shape. Our company produces billet in size 125mm×125mm. Length 3〜4m.

Bar steel rolling machines

Billets are passed through 18 rolling machines in order, to gradually extend (roll) to make bar steel. In the final rolling machine, knots and marks are stamped into the bar steel, and the bar steel is transformed into the reinforcing bar shape.

Reforming & cooling

Hot reinforcing bars are cooled down to normal temperature.

Bundling

The reinforcing bars are cut to specified lengths, and bundled in to specified numbers.

Inspection

Various inspections are carried out to check whether or not each reinforcing bar product meets the standards. Qualified products are shipped out.

Shipping

The products are loaded on trailer trucks according to the details of each order, and delivered to customers according to the specified delivery dates.