ASTM STANDARDS

We, Jonan Steel Corporation, manufacture high quality steel rods for reinforced concrete based on advanced technology and cutting-edge facilities.

- Product display

- Our company's products, supported by our trustworthy technological power, have established its position as a reliable brand.

- Product standard list

- Our goal is to manufacture excellent products day and night, under strict quality control system. We correspond to overseas standard.

- Mass table

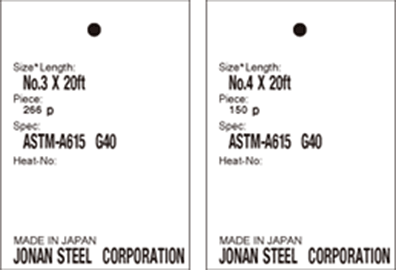

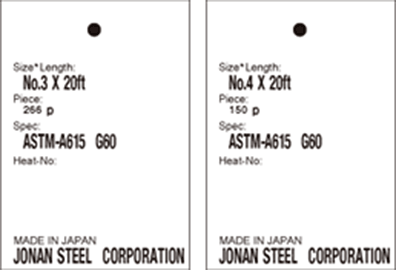

- Examples of the packing of our products can be seen here.

Product display

Our products, manufactured with solid technique, have received worldwide acclaim, and have established its position as a trusted brand.

Deformed bar/

Roll mark/

Polyester tag

ASTM-A615 Grade 40

ASTM-A615 Grade 60

Product standard list

We conduct inspections on our products to check many factors such as chemical composition, shape, dimension, mechanical property, etc. These are done under our strict quality control system, and enables us to manufacture high quality products.

Symbol of grade

| Division | Standards | Symbol of grade |

|---|---|---|

| Deformed steel bars | A615/A615M | G-40 |

| G-60 | ||

| A706/A706M | G-60 | |

| G-80 |

Chemical composition (%)

| Standards | Symbol of grade | C | Si | Mn | P | S | C.E.(※) |

|---|---|---|---|---|---|---|---|

| A615/A615M | G-40 | - | - | - | 0.060 max. | - | - |

| G-60 | |||||||

| A706/A706M | G-60 | 0.30 max. | 0.50 max. | 1.50 max. | 0.035 max. | 0.045 max. | 0.055 max. |

| G-80 |

※ C.E.(%)=C+(Mn/6)+(Cu/40)+(Ni/20)+(Cr/10)-(Mo/50)-(V/10)

Mechanical properties

| Standards | Symbol of grade |

Yield point or proof stress psi(Mpa) |

Tensile strength psi(Mpa) |

Tensile test piece |

Elongation % |

Bendability | |

|---|---|---|---|---|---|---|---|

| Bend angle | Inside radius 3(10)・4(13)・5(16) |

||||||

| A615/A615M | G-40 | 40000 min. (280) |

60000 min. (420) |

Like rolling | 12min. (※) |

180° | 3.5 × Nominal diameter |

| A615/A615M | G-60 | 60000 min. (420) |

90000 min. (620) |

Like rolling | 9min. | 180° | 3.5 × Nominal diameter |

| A706/A706M | G-60 | 60000 to 78000 (420 to 540) |

80000 min. (550) (※2) |

Like rolling | 14min. | 180° | 3.5 × Nominal diameter |

| A706/A706M | G-80 | 80000 to 98000 (550 to 675) |

100000 min. (690) (※2) |

Like rolling | 12min. | 180° | 3.5 × Nominal diameter |

(※)No3.(10) is 11% min.

(※2)Tensile strength shall not be less than 1.25 times the actual yield strength.

Dimension,mass and allowable limits of knots

| Bar Desig-nation No. | Nominal Weight, lb/ft (Nominal Mass, kg/m) | Nominal Dimensions | Deformation Requirements, in. (mm) | ||||

|---|---|---|---|---|---|---|---|

| Diameter, in. (mm) | Cross-Sectional Area in, (mm2) | Perimeter, in. (mm) | Maximum Average Spacing | Minimum Average Height | Maximum Gap (Chord of 12.5 % of Nominal Perimeter) | ||

| 3(10) | 0.376(0.560) | 0.375(9.5) | 0.11(71) | 1.178(29.9) | 0.262(6.7) | 0.015(0.38) | 0.143(3.6) |

| 4(13) | 0.668(0.994) | 0.500(12.7) | 0.20(129) | 1.571(39.9) | 0.350(8.9) | 0.020(0.51) | 0.191(4.9) |

| 5(16) | 1.043(1.552) | 0.625(15.9) | 0.31(199) | 1.963(49.9) | 0.437(11.1) | 0.028(0.71) | 0.239(6.1) |

Tolerances on mass of one piece

| No. | Tolerance |

|---|---|

| 3(10)・4(13)・5(16) | -6% min. |

Mass table

Packing (ASTM A615 Rebar to the USA)

| Size # |

Dia. (") |

Dia. (mm) |

Length (ft) |

(m) | weight (lbs/ft) |

(kg/m) | Bundle (Sub) |

(pcs/bdl.) | (kg/bdl.) |

|---|---|---|---|---|---|---|---|---|---|

| 3 | .3/8 | 9.5 | 20 | 6.096 | 0.3763 | 0.56 | 38 | 266 | 907 |

| 30 | 9.144 | 0.3763 | 1,362 | ||||||

| 40 | 12.192 | 0.3763 | 1,814 | ||||||

| 4 | .1/2 | 12.7 | 20 | 6.096 | 0.6679 | 0.994 | 30 | 150 | 909 |

| 30 | 9.144 | 0.6679 | 1,363 | ||||||

| 40 | 12.192 | 0.6679 | 1,818 | ||||||

| 5 | .5/8 | 15.9 | 20 | 6.096 | 1.0429 | 1.552 | 24 | 96 | 908 |

| 30 | 9.144 | 1.0429 | 1,362 | ||||||

| 40 | 12.192 | 1.0429 | 1,816 |